I wanted to create large amounts of pulp for papermaking at the AZ Ren Faire. The blender method won't cut it. It would take three days to get enough raw pulp to fill a five gallon bucket with the blender. Not to mention that you could only blend pulp so long before you had to let the blender cool off. The blender made nice, soft pulp (read short fibers) but not very strong paper. I must find another way…

What Already Exists

So what beaters already exist in the world and are they affordable to the individual papermaker? I did find that a lot of papermakers have made alliances with Universities & Educational Institutions to use their equipment because what exists is $$$$$$.

In alphabetical order:

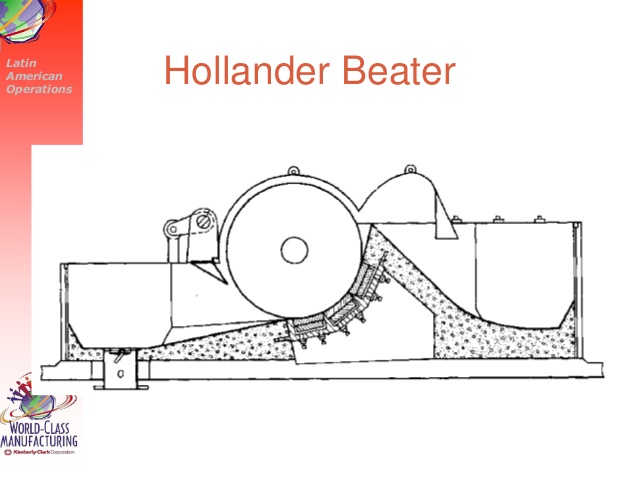

Basic Components of the Hollander

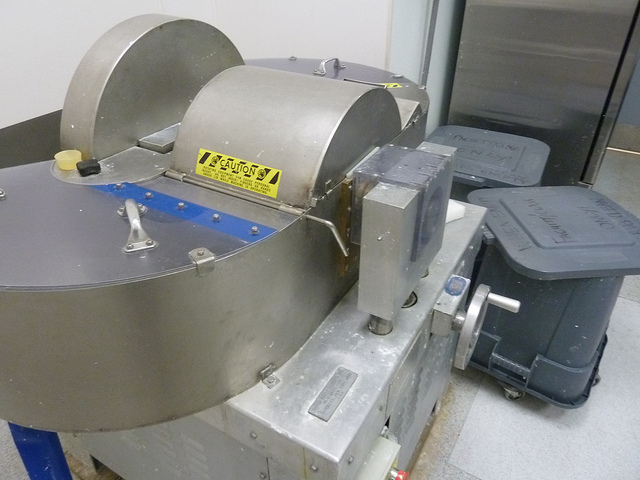

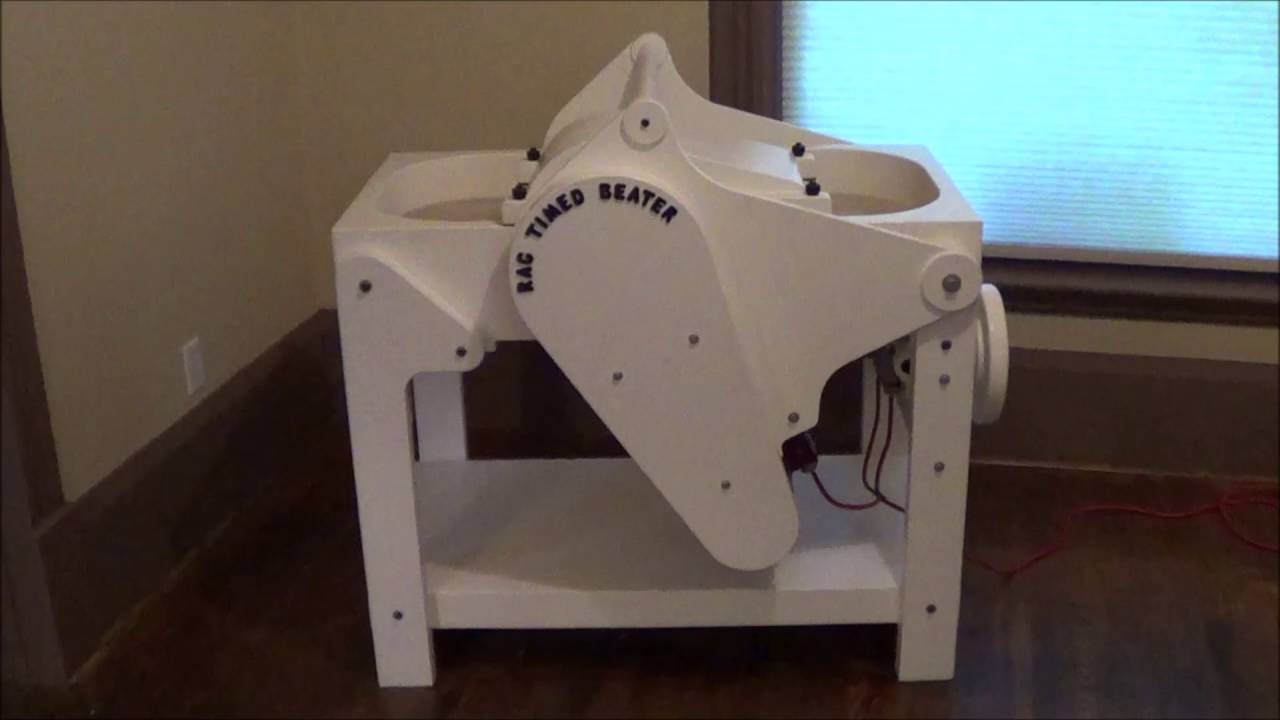

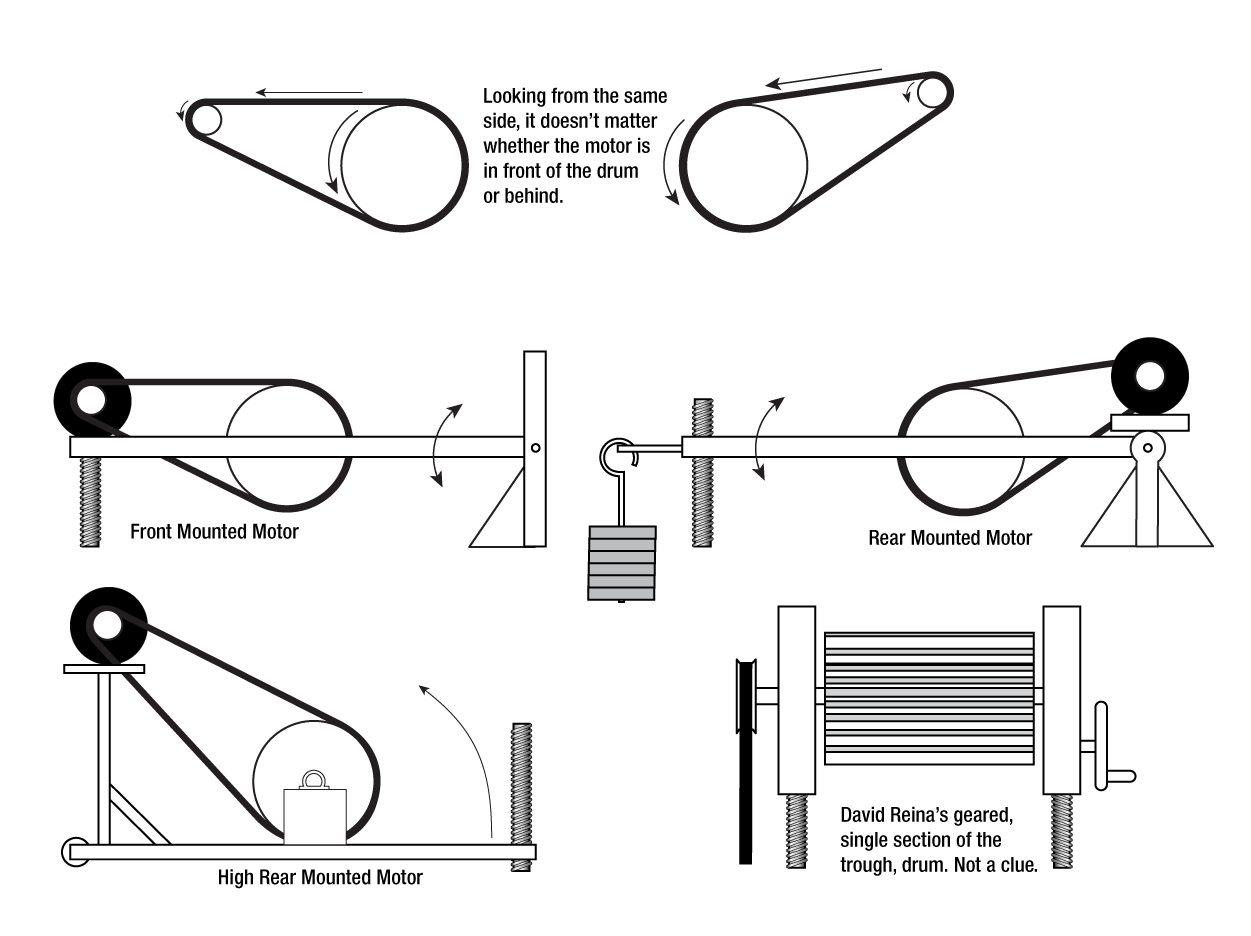

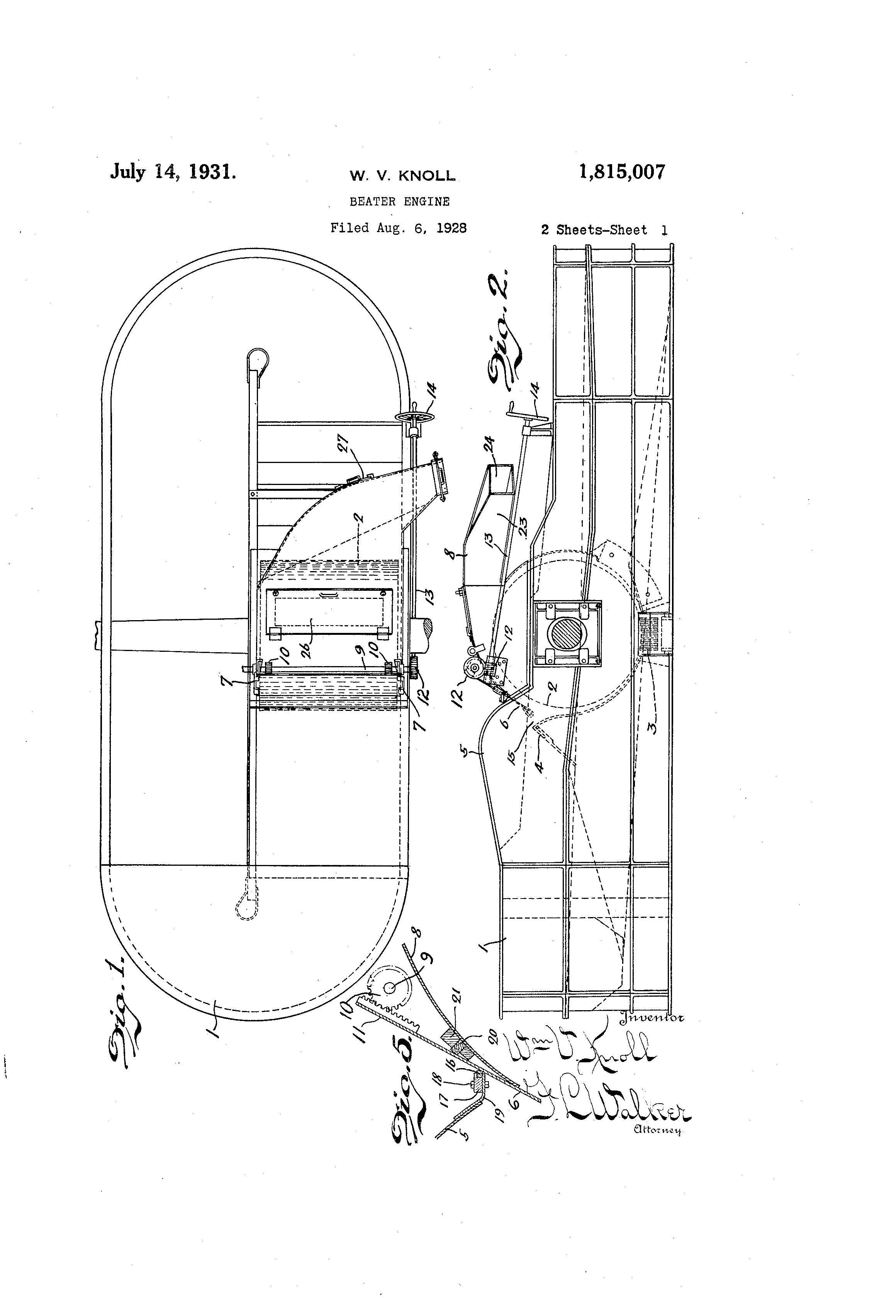

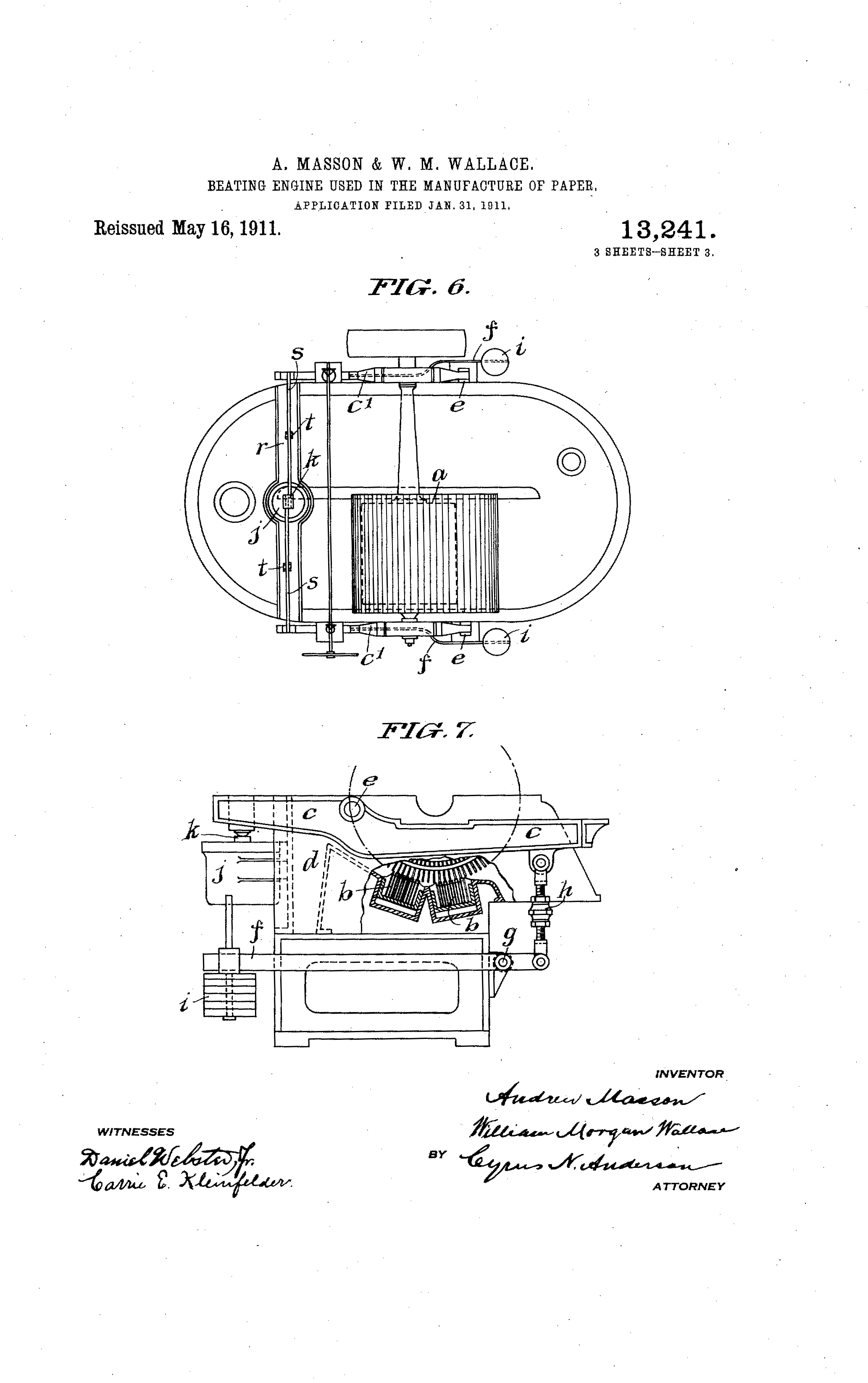

Since I decided that I was making a Hollander rather than a Valley beater (because I felt the Valley would leak like a sieve if I couldn't figure out how to seal the bedplate), how was the drum and motor going to be mounted to move up and down? So below are images that I reviewed to see the feasibility of building an arm versus a geared mechanism.

| Beaters with Arms | Beaters with Gears/Screws |

|---|---|

Fiberglass tub with drum & motor on an arm. Fiberglass tub with drum & motor on an arm. |

Fiberglass tub with drum on a geared lifting device. Fiberglass tub with drum on a geared lifting device. |

Drum mounted on the bottom of an arm with motor on top. Drum mounted on the bottom of an arm with motor on top. |

|

|

|

|

|

|

|

|

|

|

|

|

|

All the Hollanders that I looked at (in pictures, since I don't know anyone close that I can actually see a Hollander), seemed to be easier to construct an arm mounted drum and motor. At this time, I didn't know how to weld. So a lot of the components were going to be made of wood. In fact I did see David Reina build a wooden Hollander in an article of Hand Papermaking (insert the date). It was amazing but the drum was stack laminated wood. Wouldn't it float? I have also seen weights stacked on arms to keep the drum in close proximity with the bedplate.

So there are shafts that go all the way through both sides of the tub and ones that only go through one side of the trough. How is it held in place? How is downward force added? What effect does torque have on twisting of the drum's position in that small area versus a larger heavier frame? Or is it a fantastic geared mystery like the amazing engineering of David Reina?

Thoughts about arm, motor, and pulley configurations below:

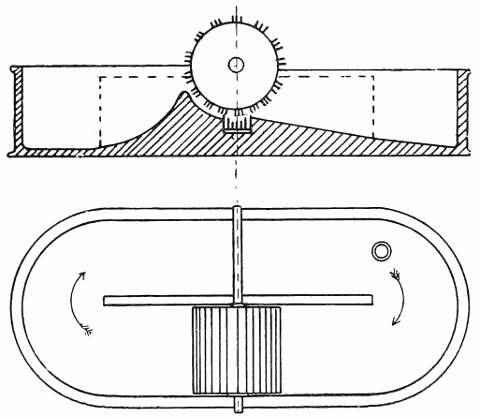

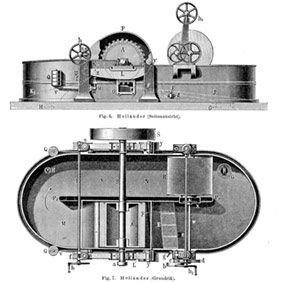

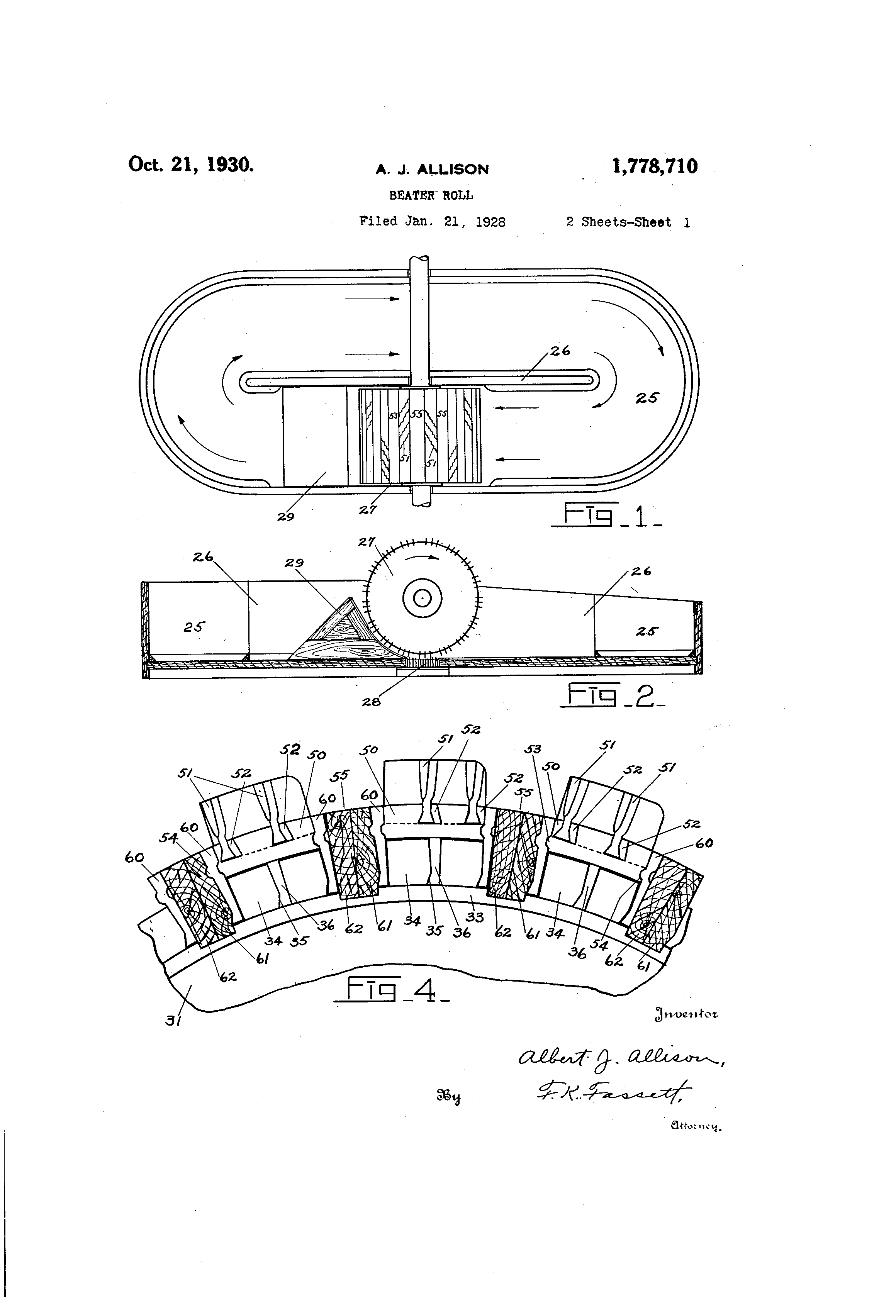

I have noticed that there was a wide variety of tub floor, bedplate position, and backfall design as well. Here are some drawings of bedplate position and patent drawings:

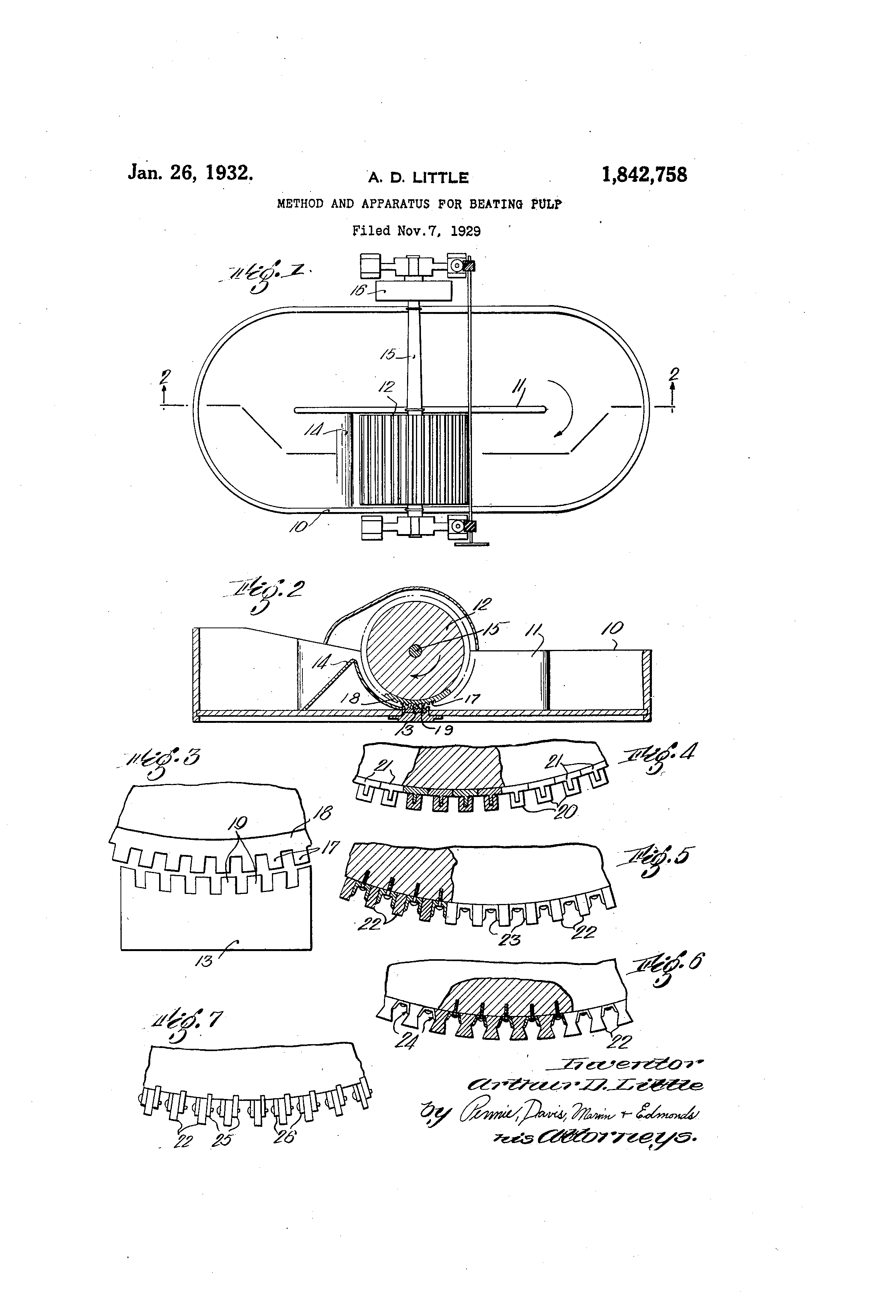

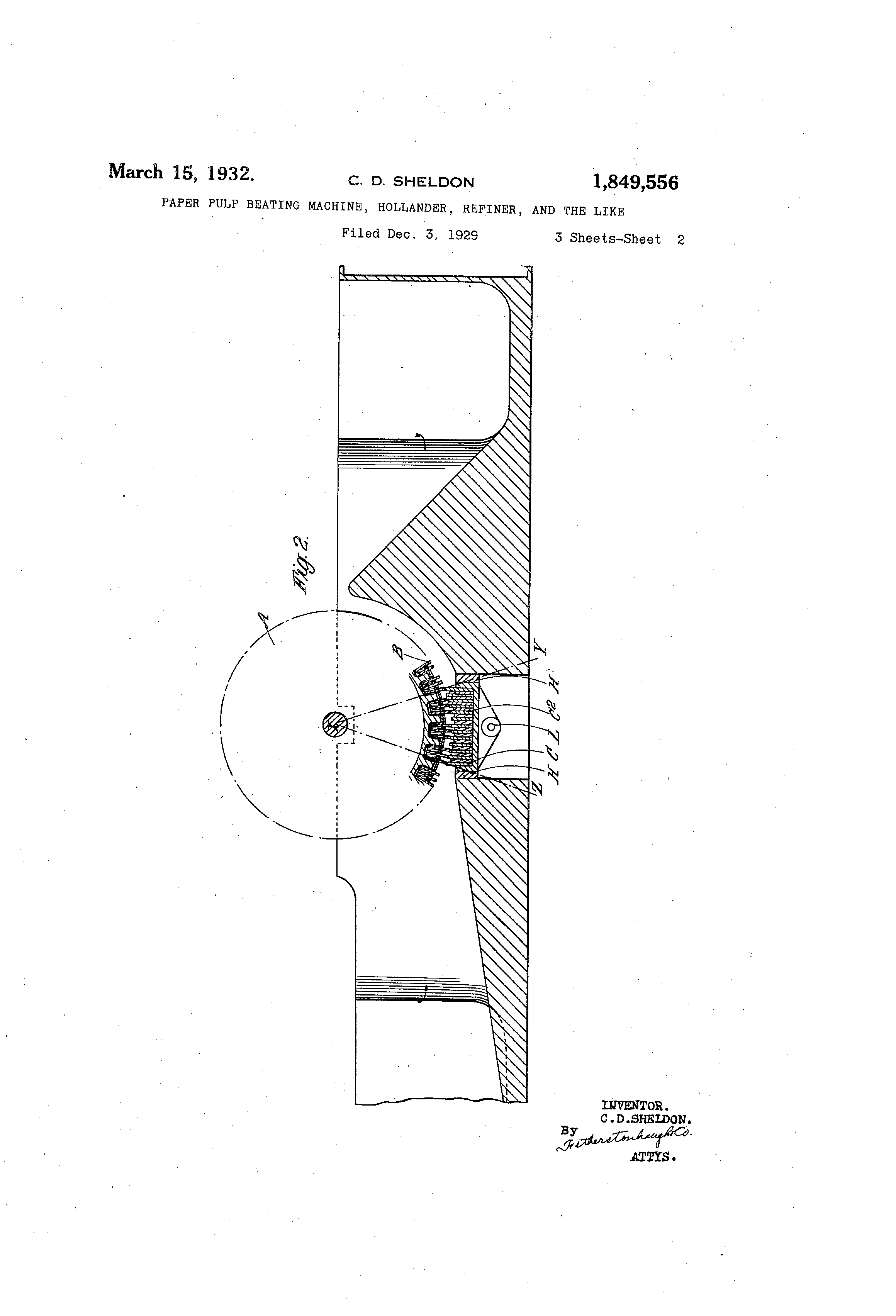

| Hollander Patent Drawings (Note position of bedplate & backfall) | |

|---|---|

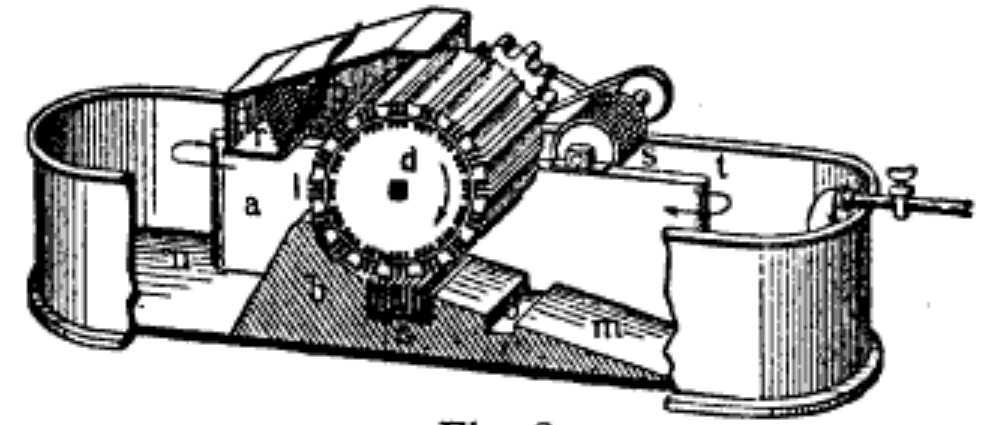

Small Bedplate, high position, short backfall. Small Bedplate, high position, short backfall. |

Bedplate embedded in the beginning of the backfall. Bedplate embedded in the beginning of the backfall. |

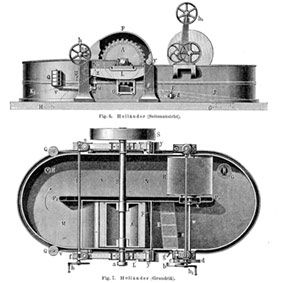

German Hollander similar position to the one above. German Hollander similar position to the one above. |

Relatively flat bed with bedplate in a dip, half drum height backfall. |

Relatively flat bed with bedplate in a dip, half drum height simple backfall. Relatively flat bed with bedplate in a dip, half drum height simple backfall. |

Bedplate in a slight rise with a high backfall. Bedplate in a slight rise with a high backfall. |

Relatively flat bed with bedplate in a dip, half drum height backfall. Relatively flat bed with bedplate in a dip, half drum height backfall. |

High ramp with bedplate recessed, even higher half drum backfall. High ramp with bedplate recessed, even higher half drum backfall. |

Short Hollander with split bedplate and tiny backfall. Short Hollander with split bedplate and tiny backfall. |

|

Note how some of the Hollander drawings have a deep tub, a ramp up to the drum and bedplate and a half drum height backfall or lower. The advantage of this is lots of water and pulp. But is the water & pulp material going to successfully get up the ramp to the drum and bedplate. If the bed and bedplate are relatively in a flat or parallel position, it doesn't take much to get the water & pulp material through the system. This requires a large drum to get the volume of the tub, because only half (or a little more) the drum is in the water because the shaft runs through the center of the drum. Can leak out of the sides of the shaft slot.